WORKFLOW

At New Plas Plastic Industries, we follow a streamlined and efficient production process to deliver high-quality plastic cups and containers. From sourcing premium raw materials to delivering finished products, each step is carefully managed to ensure consistency, safety, and customer satisfaction.

Raw Material

Selection and preparation of high-quality PP materials to ensure durable, safe, and reliable products.

Extrution Process

Melting and forming PP material into sheets or rolls, ready for thermoforming production.

Termofoming Process

Shaping plastic sheets into cups and containers using heat and precision molds.

Printing Process

Applying high-quality, multi-color printing for branding and customization on finished cups and containers.

Quality Control

Inspecting products for defects, ensuring consistency, hygiene, and adherence to quality standards.

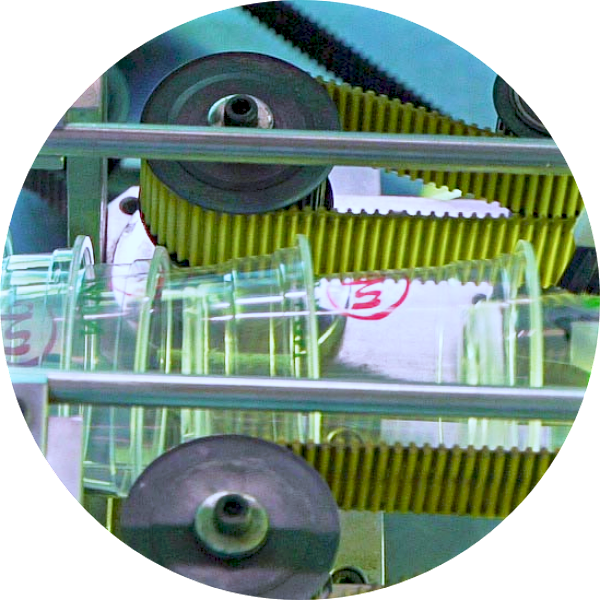

Product Counting

Automated counting to ensure accurate quantities per batch, reducing manual errors and enhancing efficiency.

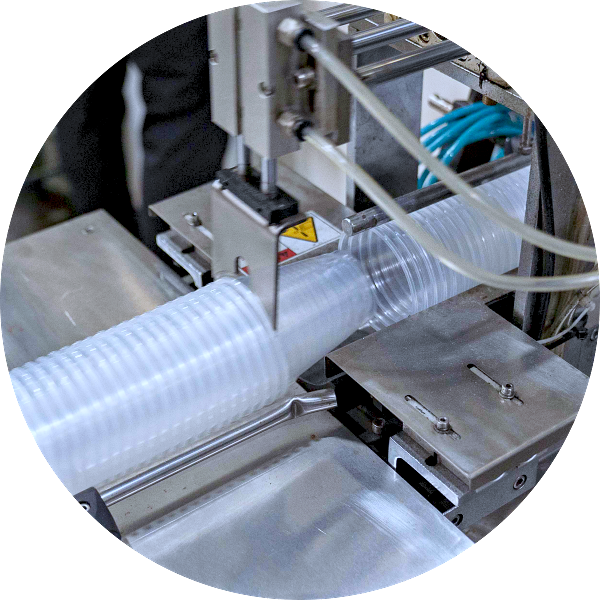

Packing

Neatly stacking and sealing products in protective packaging for safe handling and transport.

Delivery

Timely distribution to clients with secure logistics, ensuring products arrive intact and on schedule.